Navigate This Post

Is there a perfect rifle? A minimalist AR-15 rifle? Has anyone built an Armalite Rifle: Minimum Effective Dose, or A.R.M.E.D?

Colonel Jeff Cooper, USMC, the founder of Gunsite Training Academy and the father of modern pistolcraft, decades ago closely examined the M1911A1 pistol. At the time, the M1911A1 was the standard for fighting pistols in the world. However, the .45 acp service pistol was not perfect.

Col. Cooper instructed the Gunsite armorer to make certain modifications to the stock M1911A1 before it could be called a “Gunsite Pistol”. The resulting handgun was described by Jeff as having “Everything you need and nothing that you don’t.”

EDITOR’s NOTE: The following is an excerpt from the new book “The Martial Application of the Rifle” by Paul Markel. This will be the third book in the series along with the Pistol and Shotgun books now in print. Watch for the new rifle book in Sept. 2022

From the Ground Up: KE Arms Lower Receiver

While trying to come up with the “perfect rifle”, and I was examining the modern AR-15 style rifle, I thought about Col. Cooper’s mission to produce a minimalist fighting gun that had what you needed without adding things that you did not. I suppose you could call this a ballistic MED (Minimum Effective Dose) project.

Sadly, the state of our industry has people purchasing and adding things to rifles that are often highly suspect and do little more than clutter the gun and make it heavier. Yes, that lead-up is my way of saying that I decided to build an AR-15 style rifle with the idea that I would come up with a minimalist, no clutter, no fluff, gun.

One of the first places I went to was the Brownells website to start browsing and get ideas.

Lower Receiver

About 15 or 16 years ago I borrowed an AR-style rifle from James Yeager to participate in a Fighting Rifle class. The gun was unique as it was built on CAV Arms polymer, unibody lower receiver. The concept of a unibody AR lower receiver was revived by Brownells in partnership with KE Arms.

The KE Arms complete AR lower is unique in that it combines the stock, pistol grip and receiver into one unit. This makes the gun lightweight and relatively inexpensive to manufacture. The savings naturally are passed on to the consumer.

The stock on the lower is fixed, which is perfectly acceptable. Stock length is A1 not A2, meaning it has a 13 inch LoP (Length of Pull). True M16A1 stock LOP is 12.875” and the A2 is 1.35 inches.

Forgotten Upper Receiver

For the upper receiver, I looked in my shop and into a bin of AR parts that I have been accumulating for decades. A good while back, my friend Randy Luth, founder of DPMS and Luth AR, sent me a box of AR parts. One of the parts was a stripped AR upper receiver that was unique in that it had no forward assist (FA) mechanism nor a spring-loaded dust cover. However, the upper did include M1913 Picatinny rails, not just on the top, but on the left and right.

I must confess, I used all of the other AR parts that Randy sent me, but that upper receiver has been sitting in my parts bin waiting for me to do something with it. Well, the time is now. (This is one reason I never get rid of miscellaneous gun parts)

You might be thinking, “But, there is no forward assist, the gun won’t work.” Folks, I have been running an M16/M4/AR for better than 30 years now. Searching my memory, and I have a pretty clear one, I cannot recall a single time when tapping the forward assist was what I needed to do to keep the gun running. Yes, a dirty, dusty, gritty AR bolt might need a push on the rarest occasion. That is why Gene Stoner put the bevel or cut out on the bolt carrier, so you could nudge it with your thumb or finger.

What I have witnessed throughout the years is that tapping the forward assist on the M4/AR has become a nervous tick for shooters. I’ve seen them load their rifle and then take their dominant hand off of the grip to tap the FA. Generally they tap it at least twice.

There is very little wiggle room in the chamber of a rifle. If the bolt refuses to seat after you have nudged the BCG with your thumb, something is awry. Fun story. Back when I was training the military, we were on a field exercise where the troops were firing blanks from their M4’s. One young man had loaded his blank 5.56mm cartridges in his magazine backwards. Yes, that happened.

When this young trooper attempted to chamber a round, the backward blank cartridge naturally failed to chamber and the bolt was half open. Undaunted, the man pounded away on the forward assist mechanism until the cartridge was driven into the chamber. We had quite a fun time driving the blank cartridge out of the chamber. The young man, in his defense, had been taught that if the bolt failed to seat, he was to push the FA until it did so. No one had ever said to this young man, “If the bolt does not close with one tap, STOP!”

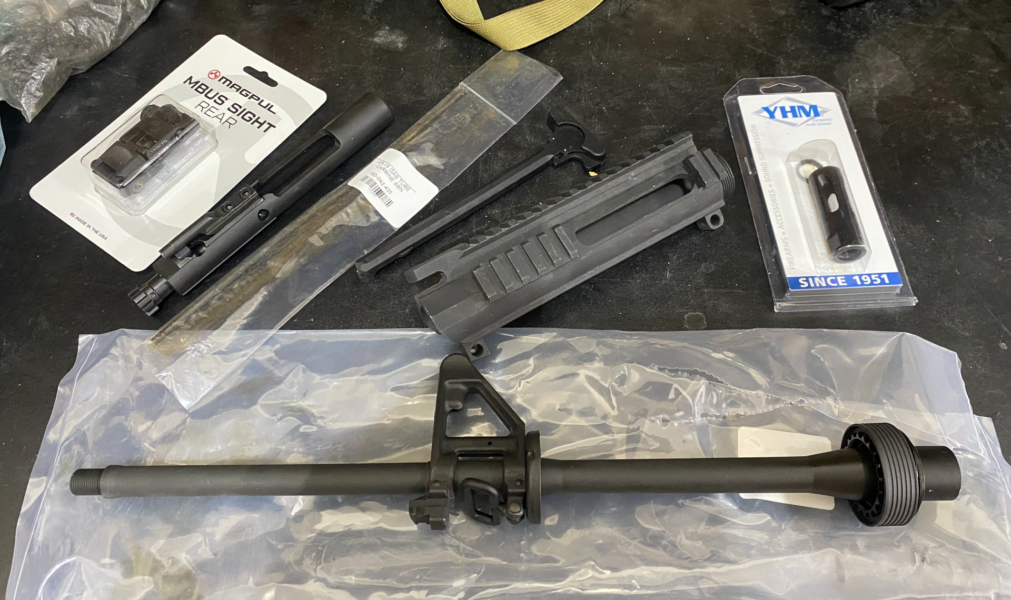

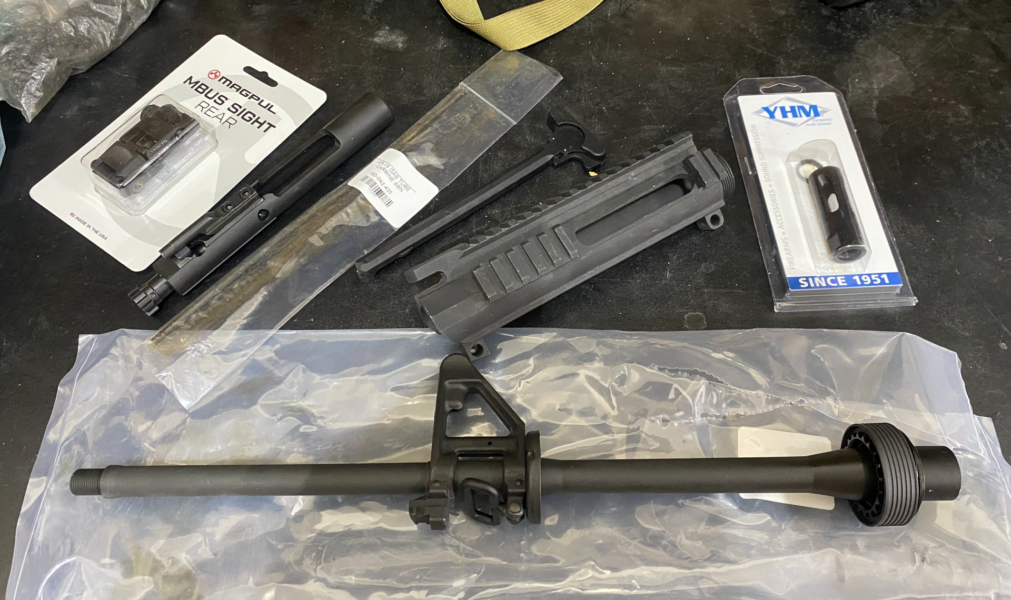

The Barrel and Other Parts

As this perfect rifle” build will be for a rifle not a rifle caliber pistol, I need an AFT friendly length. I returned to the Br”ownells website and selected a Brownells brand 16-inch carbine length barrel with an A2 front sight housing. The barrel came with all of the mounting hardware, save a gas tube. A gas tube of the corresponding length was ordered as well.

The barrel ships minus a muzzle device, for this I decided to go with a low profile Yankee Hill Manufacturing flash hider. This part and the Magpul BUIS rear back-up sight also were picked up from Brownells.

Additional Parts

Diving back into my parts bin, I had a complete AR-15 bolt carrier group and I must admit that I have more AR charging handles than I have rifles. The KE Arms complete lower receiver would arrive with the trigger, buffer and spring and all the various controls and parts necessary.

I have assembled numerous AR lowers in my time. For this project I did not feel like I needed the practice. Besides, for the price, I was perfectly happy to let KE Arms install the trigger, magazine hold-open, magazine catch, etc.

Regarding the handguard or the forend, I decided to order an MOE version from Magpul as well as a cantilever rail mount to pair with the handguard. One accessory that any defensive rifle must have is a white light. I would be adding one to the gun for this project. The last item I ordered from Magpul was black Gen3 Pmags.

Assembly

The KE Arms lower, being the “firearm” portion, had to be picked up from our FFL guy. The rest of the parts arrived in brown boxes from Brownells and Magpul. Laying all of the parts out on my workbench, I visualized the assembly process. That is when I realized that the gas tube did not come with the tiny little roll pin needed to secure it in place in the front sight housing.

Fortunately, I have been at this game for quite a long time. Back to my part tote I went. Inside the bin was a ziplock bag full of miscellaneous AR parts; detent pins, tiny springs, clips, gas rings, and yes, a teenie, tiny roll pin for the gas tube.

A piece of advice, if you have never assembled an AR before, skip Youtube and go straight to the Brownells website and watch their “How to Build an AR-15” series. Back in the old days, I watched the DVD version. Not only will their professional gunsmiths show you how to put it all together, they will recommend the dedicated tools to get the job done right. At the very least, you are going to need an M4/AR Armorer’s wrench and a roll pin punch set.

Also, remember to get some threadlock compound. All the threads on your AR should be coated with threadlock before final assembly.

With the upper receiver fully assembled, it was time to mate it with the KE Arms lower. The pivot and takedown pins that come with the unibody lower are more like an HK pin than traditional AR pins. They can be pulled completely out and then re-installed.

*Take note; even though the pivot and takedown pins look similar, they are different lengths, just like a typical AR. It is possible to inadvertently switch them which this author might have done. Swapping these pins will allow an ever so slight play between the upper and lower receivers which can and will cause stoppages.

At press time, we have only put about 100 rounds through the A.R.M.E.D. As long as the author ensured the takedown and pivot pins were in the correct holes, the gun ran fine. We will be testing it much more, but production deadlines need to be met and articles need to be printed.

Professor Paul Markel

Latest posts by Professor Paul Markel (see all)

- Tactical Masturbation: Top 3 Stupid Human Tricks - July 8th, 2024

- Blood Trail: Fearless Fiction - June 21st, 2024

- SOTG and SB Tactical Celebrate Brace Ruling - June 20th, 2024

- Shotgun Accessories: Practical and Useful - June 14th, 2024

- Tactical Rifle Tips: Transition Drills - January 5th, 2024

Recent Comments